Brand Products

Products

Contact Us

Service Hotline: 86-531-85866780

Email:info@coolwaysd.com

No. 699, Huasheng Road, Tianqiao District, Jinan City, Shandong Province, China

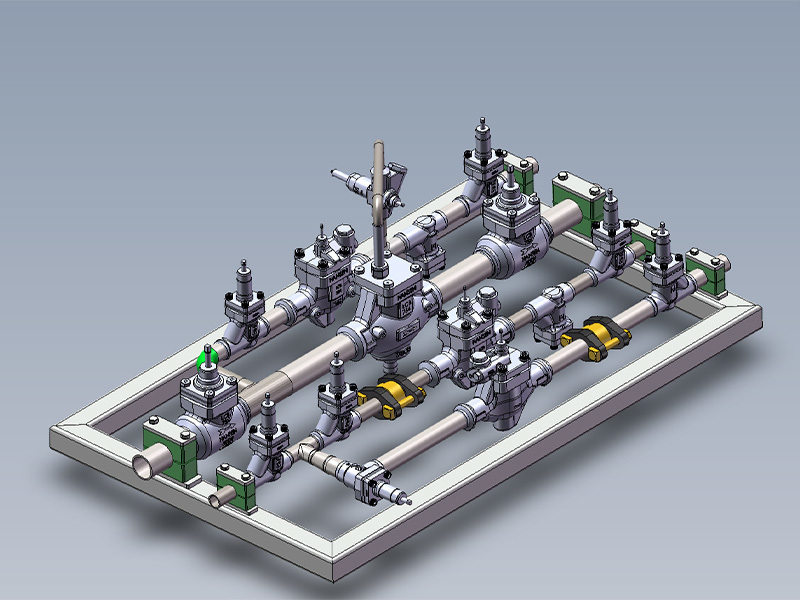

Evaporator Hot Gas Defrost Valve Assembly System Planning Proposal

This solution aims to design an integrated and modular evaporator hot gas defrost valve group system to address the pain points of evaporator systems in cold chain storage, food processing, chemical industry, etc., in terms of defrost control, liquid supply regulation, and energy efficiency optimization. By integrating functional modules such as hot gas defrosting, liquid supply control, and pressure regulation, it reduces on-site installation complexity, improves system reliability and operating efficiency, and lowers the total lifecycle cost.

Keywords:

Details

I. Project Background and Objectives

This solution aims to design an integrated and modular evaporator hot gas defrost valve group system to address the pain points of evaporator systems in cold chain storage, food processing, and chemical industries in terms of defrost control, liquid supply regulation, and energy efficiency optimization. By integrating functional modules such as hot gas defrosting, liquid supply control, and pressure regulation, it reduces on-site installation complexity, improves system reliability and operating efficiency, and lowers the total lifecycle cost.

II. Core System Function Design

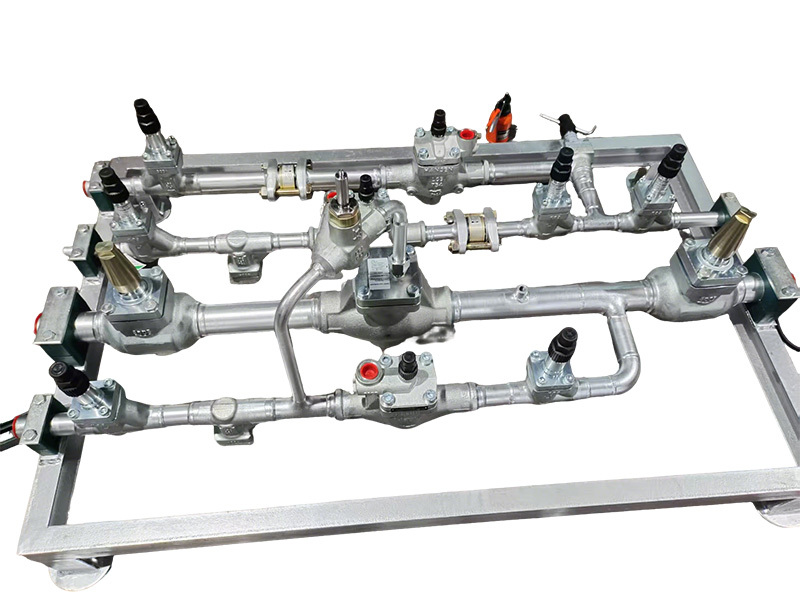

1. Hot Gas Defrosting Functional Module

Hot gas defrost valve group: Uses high-precision pneumatic/electric control valves to achieve precise allocation and switching of hot gas (from compressor exhaust), quickly melting frost on the evaporator surface, and restoring heat exchange efficiency.

Defrost logic control: Supports timed defrosting, temperature difference-triggered defrosting (e.g., evaporator surface temperature below the set value), or pressure difference-triggered defrosting (e.g., abnormal increase in return gas pressure), adapting to different operating conditions.

2. Liquid Supply and Direct Expansion Control

Electronic expansion valve (EXV) or metering liquid supply valve: Dynamically adjusts the refrigerant supply according to the evaporator load, optimizing the liquid supply method to improve the system's coefficient of performance (COP).

Liquid supply solenoid valve: Works in conjunction with the defrosting system to automatically cut off the liquid supply during defrosting, preventing liquid refrigerant from entering the compressor and causing liquid hammer.

3. Defrost Drainage Pressure Balance

Check valve + drainage regulating valve combination: After defrosting, quickly drains the remaining liquid refrigerant from the evaporator to avoid affecting the next refrigeration cycle.

4. Suction Two-Step Opening Valve Low-Temperature Efficiency Optimization

Suction pressure pneumatic valve: Maintains the evaporator outlet to achieve two-step opening, adapting to the evaporation pressure requirements under low-temperature conditions (e.g., below -40°C), and improving the heat exchange efficiency in low-temperature environments. Automatically opens the auxiliary circuit under low-temperature conditions to prevent the suction pressure from being too low and causing compressor surge.

III. Technological Innovation and Advantages

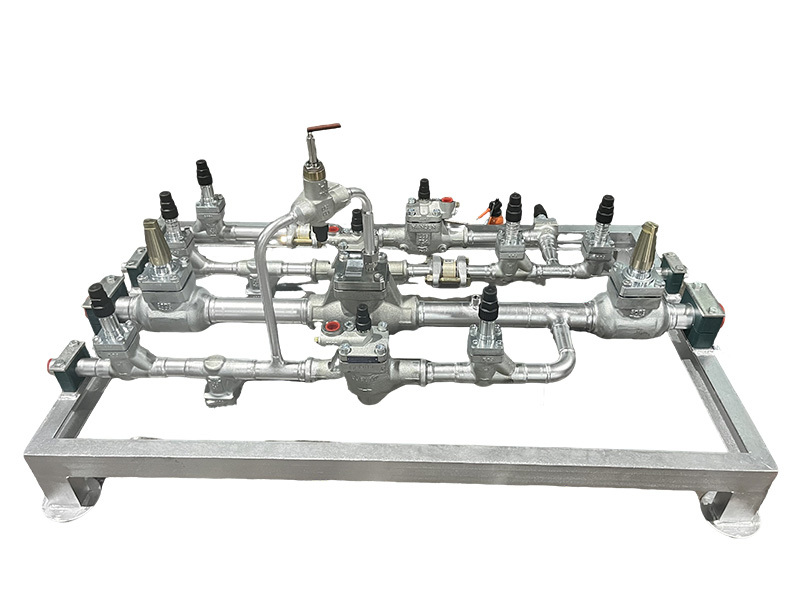

1. Modular Integrated Design

Function integration: Integrates liquid supply valves, hot gas defrost valves, pressure regulating valves, solenoid valves, etc., into the same valve group frame, reducing piping connection points and lowering the risk of leakage.

Combination of standardization and customization: Core valves (such as hot gas defrost valves, PRV) use uniformly specified parts (valve body, actuator, seals), supporting non-standard customization (such as interface size, pressure level, control signal type) to meet customer's individual needs.

2. Installation and Maintenance Optimization

Reduced on-site welding: The valve group uses flange connections or clamp quick-fitting design, pre-assembled and then hoisted as a whole. On-site, only piping and power/gas sources need to be connected, reducing installation time by more than 50%.

Leak-proof sealing design: Eliminates flange gaskets and uses welded valve bodies or metal hard seal structures to eliminate leakage problems caused by gasket aging; bottom-less stop valve stem design avoids liquid accumulation and corrosion risks.

3. Intelligent Control Function

Multi-mode control: Supports pressure regulating valve (PRV) and solenoid valve linkage control, or integrates PLC/DCS system to achieve remote electric control (4-20mA signal, Modbus protocol), adapting to the needs of automated production lines.

Manual emergency function: All valves are standard-equipped with manual opening devices (such as hand wheels or handles) for quick switching to manual mode in case of power failure or control system malfunction, ensuring system safety.

IV. Application Scenarios and Benefit Analysis

1. Typical Application Scenarios

Cold storage evaporator system: Fast defrosting reduces downtime and improves cold storage utilization; low-temperature suction regulation ensures stable operation below -40°C.

Food processing quick-freezing equipment: Precise liquid supply and hot gas defrosting work together to avoid fluctuations in the quality of frozen products.

Chemical low-temperature reaction device: High-reliability valve group design adapts to corrosive media and extreme temperature environments.

2. Customer Value

Cost savings: Modular design reduces the number of spare parts (such as hot gas defrost valves, PRV common parts), lowering inventory costs; standardized training shortens the learning cycle for maintenance personnel.

Energy efficiency improvement: Hot gas defrosting efficiency is improved by more than 30%, suction pressure regulation reduces compressor power consumption, and the overall energy saving rate can reach 15%-20%.

Enhanced reliability: Leak-proof design extends equipment life, and manual emergency function reduces unplanned downtime losses.

V. Conclusion

This solution provides customers with a highly efficient, reliable, and low-maintenance cost evaporator system solution by integrating hot gas defrosting, liquid supply regulation, and pressure control functional modules, combined with modular design and intelligent control technology. In the future, product performance can be continuously optimized based on customer feedback, and expanded to more industrial refrigeration application scenarios.

Download

Get a free quote

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

If you have more requirements, please click the button to submit the information, and we will reply to you as soon as possible.

If you have more requirements, click the button to submit information, and we will reply to you as soon as possible.

Contact Us

Please contact us in the correct way, and we will provide you with detailed information.

No. 699, Huasheng Road, Tianqiao District, Jinan City, Shandong Province, China